glass candle jar are a common household item that not only lights up a room, but also serves as a decoration. In order to make the candle holders more beautiful, Sunny glassware will use the cup kiln to bake and heat the electroplating machine to put aluminum wires to process the electroplating process. Sunny glassware will handle many problems that are easy to occur in a refined and perfect manner, and 90% of its peers cannot do it. The electroplating process can form a layer of metal film on the surface of the candle holder, thereby improving the hardness, wear resistance, heat resistance and light reflection ability of the candle holder, and can also play a decorative role.

Sunny glassware pre-plating treatment process is one of the few in the industry. Because the performance of the coating is different from that of the base metal, it has new characteristics. According to the function of the coating, it is divided into protective coating, decorative coating and other functional coatings. Electroplating is the abbreviation of electrolytic metal plating method. Electroplating is to immerse the plated parts (products) in the potion containing the metal ions to be plated and connect the cathode. The other end of the potion is placed with an appropriate anode (soluble or insoluble). After direct current is applied, the surface of the plated part is instant A method of depositing a thin metal film. A simple understanding is the change or combination of physics and chemistry. At present, the more commonly encountered electroplating methods: aqueous solution electroplating (barrel plating, rack plating, continuous plating), chemical plating.

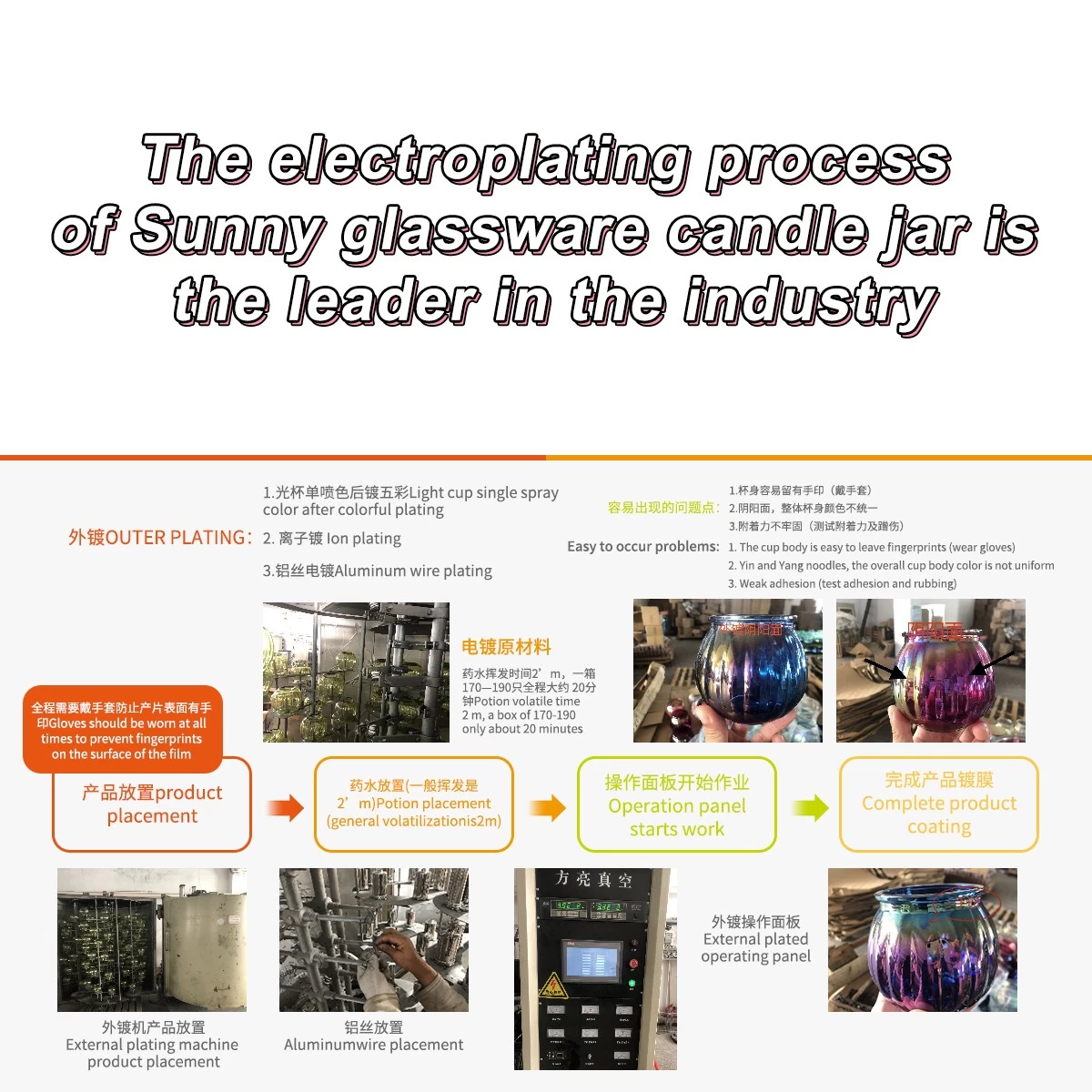

There are two types of electroplating processes for glass candle jar:

Internal and external plating.

The process flow of internal electroplating is to clean the light cup first, then bake and heat the cup body kiln, then place aluminum wire or aluminum sheet in the electroplating machine, pre-vacuumize, evacuate at high temperature, the aluminum wire volatilizes, and complete the electroplating cup. The process flow of external electroplating is five-color plating after single-color spraying of light cup, ion plating, and aluminum wire electroplating. Gloves are required to prevent fingerprints on the surface of the production film during the whole process. The product is placed, the potion is placed, the operation panel starts to work, and the product coating is completed.

During the glass candle jar electroplating process, some details need to be paid attention to to ensure the quality of the product. First of all, if the aluminum wire does not volatilize completely, the coating of the optical cup will be transparent and black after spraying. Secondly, you need to wear gloves throughout the process to prevent fingerprints on the surface of the production film. Finally, the operation panel needs to be carefully operated to ensure the quality of the product coating.Sunny adapts extra six steps for inspection,No major quality complaints on products produced for 9 consecutive years.