As the saying goes, find the right person and do the right thing, and you will get twice the result with half the effort.

American customer Amy needs to purchase 80,000 plain glass candle vessels. I don't know why she wants to use the pressing process to make them. I looked at her sample drawings. The shape of this glass candle vessel is that the mouth and bottom size are smaller than the cup body, and there is no pattern. If this candle vessel is made by pressing technology, the pressing mold forming process has two obvious disadvantages: the cup wall is thick, the product weight increases, there will be seams on the cup body, which will increase the transportation cost, and the outer wall of the cup will feel and look bad. Based on the appearance and purchase volume of this glass candle vessel, I recommend that customers use machine blowing technology, which not only saves transportation costs, but also does not need to increase the polishing process. The most important thing is that it achieves the highest cost-effectiveness in terms of cost control and beauty. After in-depth communication, Amy agreed with my point of view very much. She said that everyone has their own expertise, and it is cost-effective and reassuring to give the order to Sunny Glassware.

I receive many inquiries from countries around the world every day. Customers often ask, why don't we accept orders for glass candle vessels in dozens or hundreds of purchases? Why are there multiple quotation plans for the same product and the same number of products? The main reason is related to the product process. The shape, internal structure, thickness, etc. of the glass candle vessel all affect the selection of the appropriate production process. There are three common molding process technologies.

1. Hand-blown molding

Hand-blown is one of the traditional glass making methods and the most primitive production method. The process is relatively simple. It only requires blowing the molten glass into the mold, and then manually processing and making it into a glass candle vessel. The hand-blown glass candle vessel focuses on the handmade art style, and the personalization of the shape and material is very obvious. However, its production efficiency is very low and it is suitable for small batch orders.

2. Machine compressed molding

Machine compression molding is a production method commonly used by modern industry in the production of glass candle vessels. It uses multi-stage molds to press the molten glass into the required shape on the mold. The cup shape of this method is highly accurate and uniform in color. The advantages of compression molding are high production efficiency, lower cost than manual production, and good quality consistency of the cup. It is almost standard today with a wide variety of glass cups. However, the mold production cost is high and it is not easy to replace in batches. If the production volume is small, the unit cost will be relatively high.

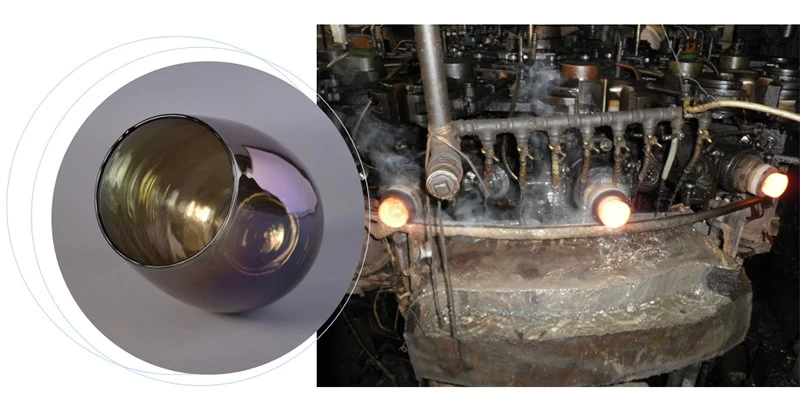

3. Machine Blowing Molding

Machine blowing molding is a recently adopted method for manufacturing glass candle vessels. Its principle is to heat the glass particles into a molten state, then inject them into the mold, and blow air through the machine to make the glass fill the mold surface and become the desired shape. Machine blowing molding can realize automated production, and its production efficiency and production accuracy are better than manual production. However, the production difficulty of machine blowing molding is higher than that of machine die molding. The operation of the production line requires strict control of air pressure, temperature and process, and requires a certain amount of capital investment. However, compared with manual production and machine die molding, the cost of machine blowing is relatively low, and it has a good application prospect for large-scale production needs.

If the quality of glass candle vessels is good, there will always be no shortage of orders. On the basis of ensuring quality, we use a professional perspective to help customers choose the right production process to avoid unnecessary costs, and 90% of customers will repurchase. With the strong support of Sunny Glassware, all the customers have good profit and get 30% sales increase every year.