When an exquisitely designed embossed perfume bottle faced the desperate situation of being "impossible to mass-produce," how did Sunny Glassware leverage its profound technical expertise and flexible supply chain to turn the situation around within 45 days, ultimately securing a long-term exclusive cooperation agreement with the client?

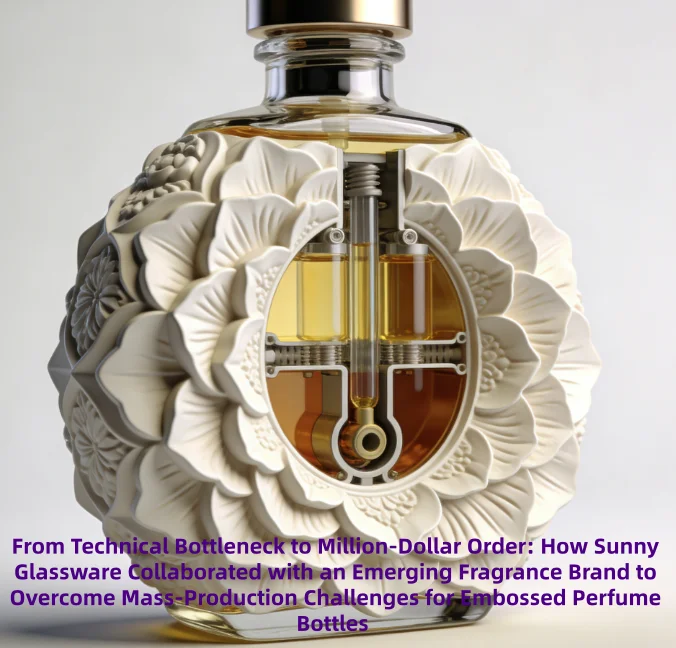

In early 2023, Sunny Glassware received a detailed inquiry from a European emerging high-end fragrance brand. Its creative director attached a highly artistic 3D design: the bottle needed to feature complex multi-layered embossed floral patterns, and the internal structure had to be compatible with the brand’s unique biphasic essential oil formula.

The requirements were stringent:

- Perfectly replicate the design: Embossed textures must be clear, three-dimensional, and finely tactile.

- Chemical stability: The glass material must withstand high-concentration essential oils without degradation over long-term storage.

- Mass-production feasibility: An initial order of 50,000 pieces, with a stable monthly supply of 20,000 pieces thereafter.

- Tight deadline: Samples confirmation and mass production within 90 days.

This was not just an order but a rigorous test of Sunny Glassware extreme engineering capabilities and comprehensive supply chain strength.

After the initial excitement, the project quickly entered deep waters. During the trial production phase, Sunny Glassware engineering team identified two critical bottlenecks:

1.Embossed demolding challenge: The intricate concave embossed patterns easily jammed in traditional molds, resulting in a demolding rate of only 30% and an extremely high defect rate in the bottle bodies.

2. Glaze compatibility crisis: The luxurious gold glaze specified by the client, when combined with the special soda-lime glass selected to ensure chemical stability, developed localized oxidation patches and uneven coloring after high-temperature firing.

The project timeline was at risk. Conventional solutions meant either compromising on the design or changing the base material—both of which could undermine the product core value and jeopardize the collaboration.

Faced with the deadlock, Sunny Glassware refused to propose compromises and instead formed a "special task force" comprising R&D, engineering, production, and quality control.

- The team abandoned the traditional one-piece mold solution and innovatively adopted a "multi-segment precision steel mold." By dividing the embossed areas of the bottle into multiple precisely separable modules, they achieved damage-free demolding, increasing the demolding rate to over 98%.

- To address the glaze issue, the R&D team conducted 217 firing tests within 15 days. Ultimately, through an original "low-temperature gradient sintering process" and adding a special intermediate layer to the glass substrate, they perfectly resolved the glaze adhesion and color rendering issues, achieving the "warm, flowing gold" texture required in the design.

Throughout the process, Sunny Glassware maintained weekly communication with the client via email, sharing high-definition images, videos, and reports to transparently showcase problems, test data, and progress. This "no-black-box" collaboration approach greatly enhanced the client trust and patience.

After 45 days, when three batches of near-perfect samples, along with detailed test reports (including compatibility tests, drop tests, and long-term storage simulation reports), were presented to the client, their feedback was unequivocal: "You not only realized the design but elevated it."

Results:

- The initial order was increased from 50,000 to 150,000 pieces, accompanied by a three-year exclusive supply agreement.

- The client integrated Sunny Glassware into its ERP system, enabling real-time synchronization of order and production status data.

- At the new product launch event, Sunny Glassware was listed as an "artistic co-creation partner," generating significant industry brand exposure.

A Message from Sunny Glassware to Global Fragrance Brands and Procurement Leaders:

In a fiercely competitive market, a unique perfume bottle is the silent ambassador of your brand. And a partner who understands your vision and turns complex designs into reliable reality is the strongest cornerstone of your supply chain.